A Nuclear Revolution Has Just Started

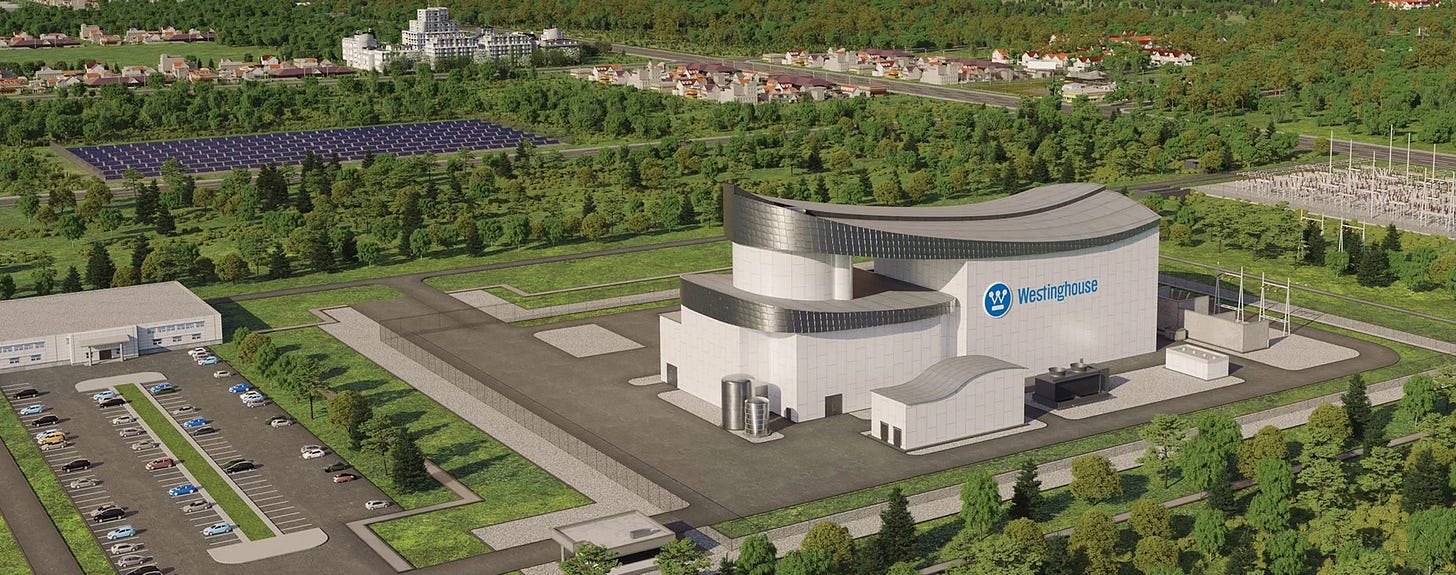

Westinghouse is set to build their first SMR power plant.

Nuclear power is by far one of the cleanest and safest energy sources we have. It stands to reason, it should be a powerhouse of our net-zero transition. Sadly, though, they are also extortionately expensive and often take well over a decade to put into operation, rendering them an unviable solution for many. However, there is a solution to this problem: small modular reactors (SMRs). SMRs promise to be far cheaper and faster to deploy than traditional nuclear reactors as they are more flexible and more material-efficient, and thanks to their ability to be built in an off-site controlled factory, they can benefit from economy of scale and even just-in-time manufacturing. But as of yet, this promise has been largely unfulfilled, with SMR project costs skyrocketing and being cancelled left, right and centre. However, Westinghouse may have solved the SMR conundrum with their AP300 SMR, which is set to become the first commercially operational SMR in the West. So, is this the start of a nuclear revolution? Or, is it a pointless shot in the dark?

A few days ago, Westinghouse announced they signed an agreement with Community Nuclear Power (CNP) to build an SMR power station in Teesside, UK, which will use four Westinghouse AP300 SMRs. They aim to fully licence the site by 2027 and provide 1 GW of power to the energy grid by 2034. This would make it the first SMR project to come online in the West by a considerable margin, and the first private commercial SMR ever! While it will be privately operated, this deal is part of the UK’s plans to quadruple its nuclear capacity by 2050, meaning that Westinghouse may have more opportunities to install SMRs in the UK.

So, why did CNP choose Westinghouse over any of the other SMRs coming to the market? Well, it’s all down to their reactor, the AP300.

Most SMRs have to rely on new, unproven reactor technology like gas cooling, molten salt cooling, or even sodium fast reactors to enable them to be shrunk down. Otherwise, they would too large and bulky to be viable for an SMR project. But not so for Westinghouse; their AP300 SMR uses the exact same light water reactor design as their larger AP1000 traditional nuclear reactor that is already licensed and in operation in the US, EU and Asia. This means there are far fewer legal and safety hoops for Westinghouse to jump through, as the technology, fuel, safety systems, and procedures of the AP300 are already approved. In turn, this makes the AP300 even cheaper to put into operation, speeds up initial deployment time, and makes it possibly the most dependable and reliable SMR out there.

As the name suggests, the AP300 has a power output of 300 MW, far less than the 1.2 GW of the AP1000, which has a fairly average power output for a nuclear power plant. This is why most customers are likely to use four or more AP300s.

But, if it uses the same technology, how is the AP300 cheaper and quicker to deploy than the AP1000?

Unlike the AP1000, the AP300 is small enough to be built off-site in a factory and shipped to location with minimal assembly happening on-site. This makes reaching critical safety points and tolerance margins far easier and cheaper, and reduces expensive construction costs by dramatically speeding up construction. In fact, Teesside’s AP300s are planned to be shipped to location in an almost fully built state in the early 2030s and will be fully installed and operational within a few years. Moreover, once orders start piling up, this factory can begin churning them out, benefiting from economy of scale, shrinking production costs even more. Despite needing four AP300s to match the output of the AP1000, the AP300 is actually more material and space-efficient. Not only does this further reduce construction costs, but it also reduces maintenance and operational costs going forward.

This is why an AP1000 costs around $15 billion and takes nearly 10 years to be built and enter commercial operation. In comparison, AP300 units are predicted to cost only $1 billion and take only a few years to be built and put into commercial operation. That means the AP300 is roughly 73.33% cheaper than the AP1000!

This $1 billion price tag was just an estimation for a few years ago, and material costs have skyrocketed since. But the price gap between the two means that the cost of the AP300 could double from this estimate and still be significantly cheaper than its bigger brother.

So, it’s no wonder CNP chose Westinghouse for their SMR project. The AP300 is an intelligently designed SMR that utilises existing, already licenced technology but packages it in a new way to save billions of dollars and years of waiting. If Westinghouse can deliver on their promises in Teesside, it would mark a vast leap forward for the nuclear industry, putting their price and deployment time far closer to solar and wind power. If this doesn’t spark a nuclear revolution, I don’t know what would.

Thanks for reading! Content like this doesn’t happen without your support. So, if you want to see more like this, don’t forget to Subscribe and follow me on BlueSky or X and help get the word out by hitting the share button below.

Sources: WNN, BBC, Westinghouse, NAMRC, Westinghouse, Energy.gov, Westinghouse, IEA, CNBC, Westinghouse, Nuclear Newswire